Automated Solutions

Integrated Solutions for Off-Site Construction

Increase plant efficiency and reduce labor requirements with integrated automated solutions.

MatchPoint DirectDrive

Achieve complete integration that is customizable to your needs with the MatchPoint® DirectDrive™ System, designed for the flexible operation of multiple MiTek machines.

MiTek Guardian Machinery Service

MiTek® Guardian™ is a preventative maintenance program that safeguards your operations from equipment malfunctions. It features scheduled technician visits, multi-point inspections, proactive maintenance, and minor repairs, ensuring your MiTek equipment is always green-lit for the work ahead.

Plant Optimization Service

Our Solution Architects provide a tailored plant layout for optimal efficiency, focusing on minimizing waste and maximizing labor productivity using 3D designs.

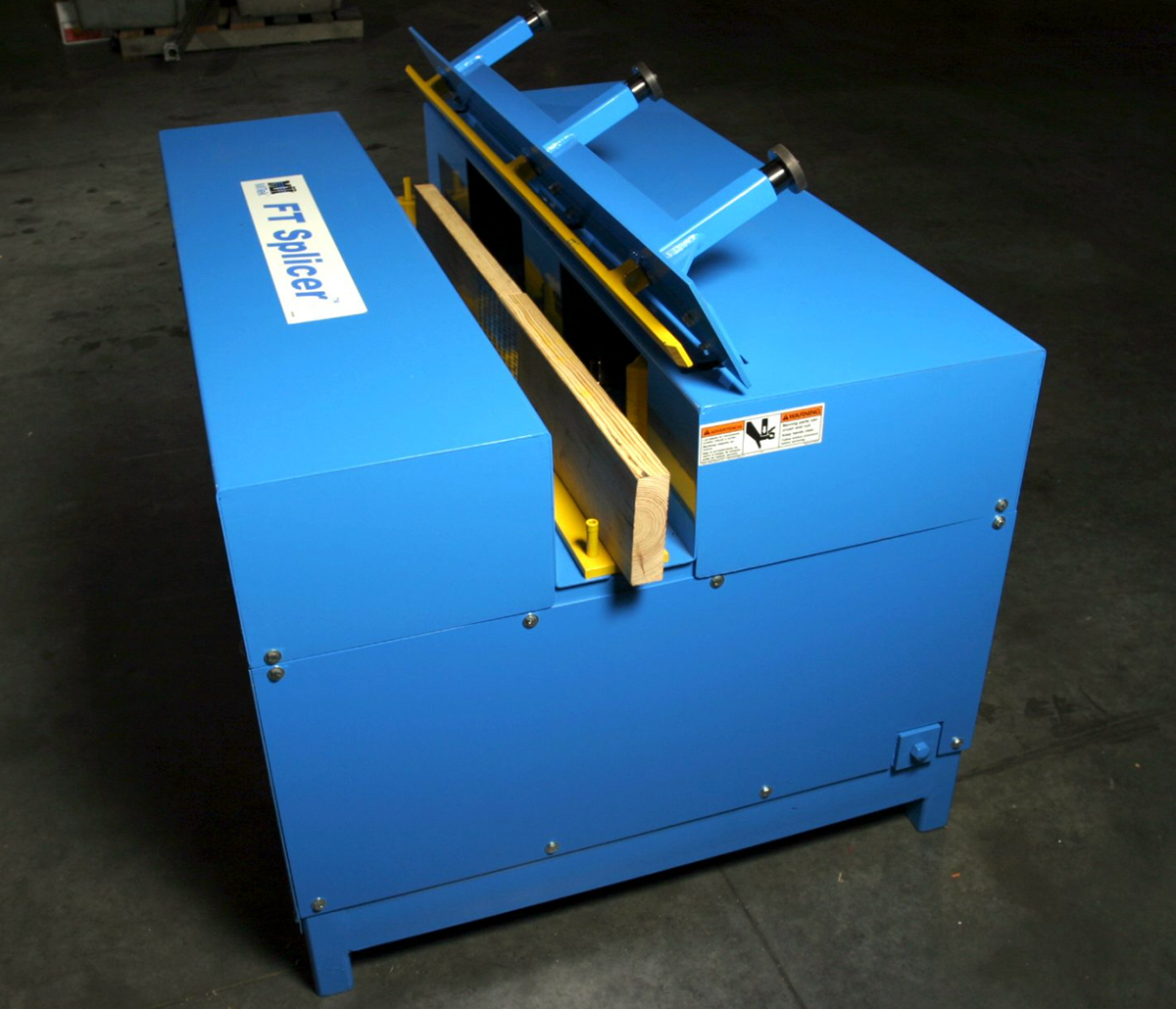

Cutting

Utilize MiTek’s wood processing equipment to achieve unmatched reliability and accuracy with your floor trusses, roof trusses, and wall panels.

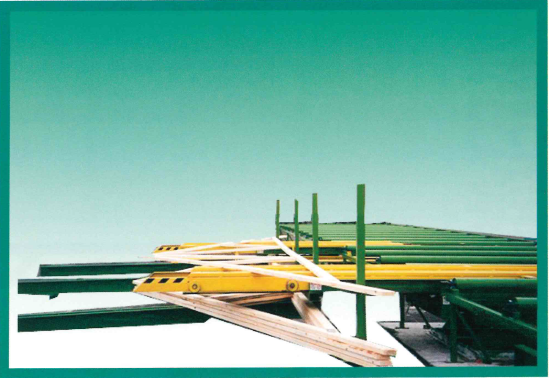

Material Handling

An efficient off-site component manufacturing operation requires integrated systems that can keep up with demand shift after shift. MiTek’s material handling solutions are fast and effective, so your productivity never slows down.

Assembly

Bring it all together with tables, jigging, lasers, and more for seamless roof truss, floor truss, and wall panel assembly. Integrate with MatchPoint® DirectDrive™ for an end-to-end plant automation solution.

Are you ready to increase reliability, flexibility, and productivity throughout your component manufacturing operation?

Talk to one of our automation experts to learn more.